As we all know, solar streetlights are composed of photovoltaic panels, batteries, light poles, and LED light fixture. After the appearance design and internal structure design, the lighting manufacturer customizes and purchases from suppliers of different components, then assembles and inspects them in the factory, and finally delivers them to customers.

Solar light factories, usually do not have the ability to produce batteries and solar panels at the same time, and they play a major role in street lights, so the quality control of these components is very important.

In order to respond to some FALSE parameters cut corner behaviors in the market and control the quality of the supply chain, we will test our solar panels and batteries with professional testing instruments.

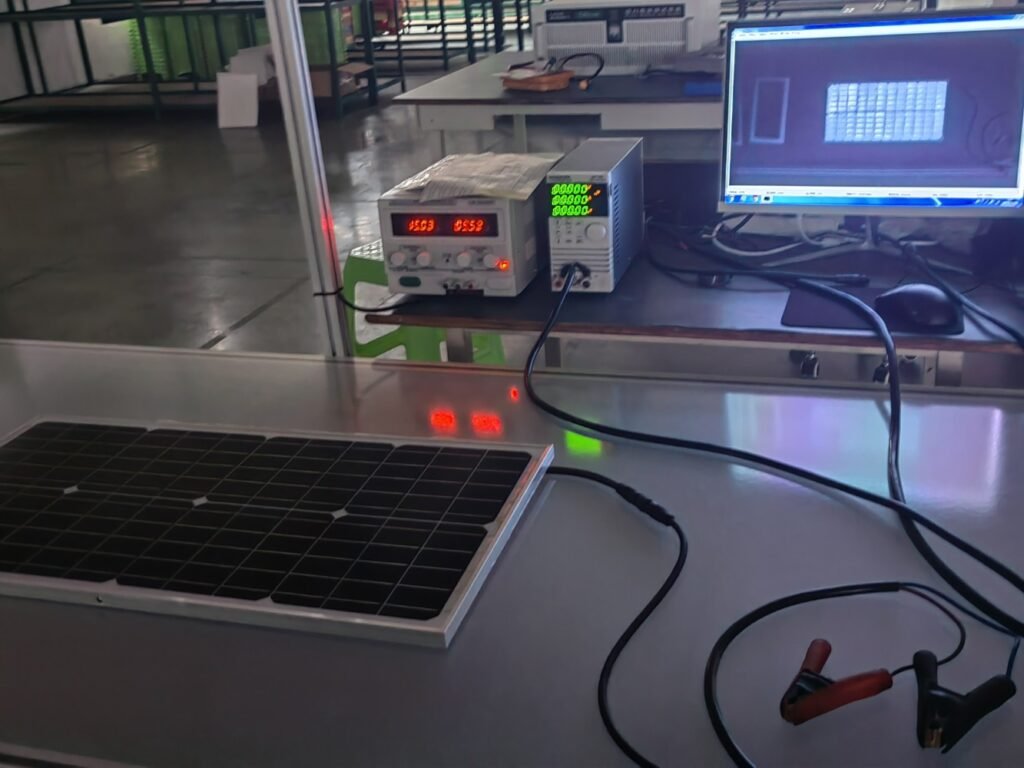

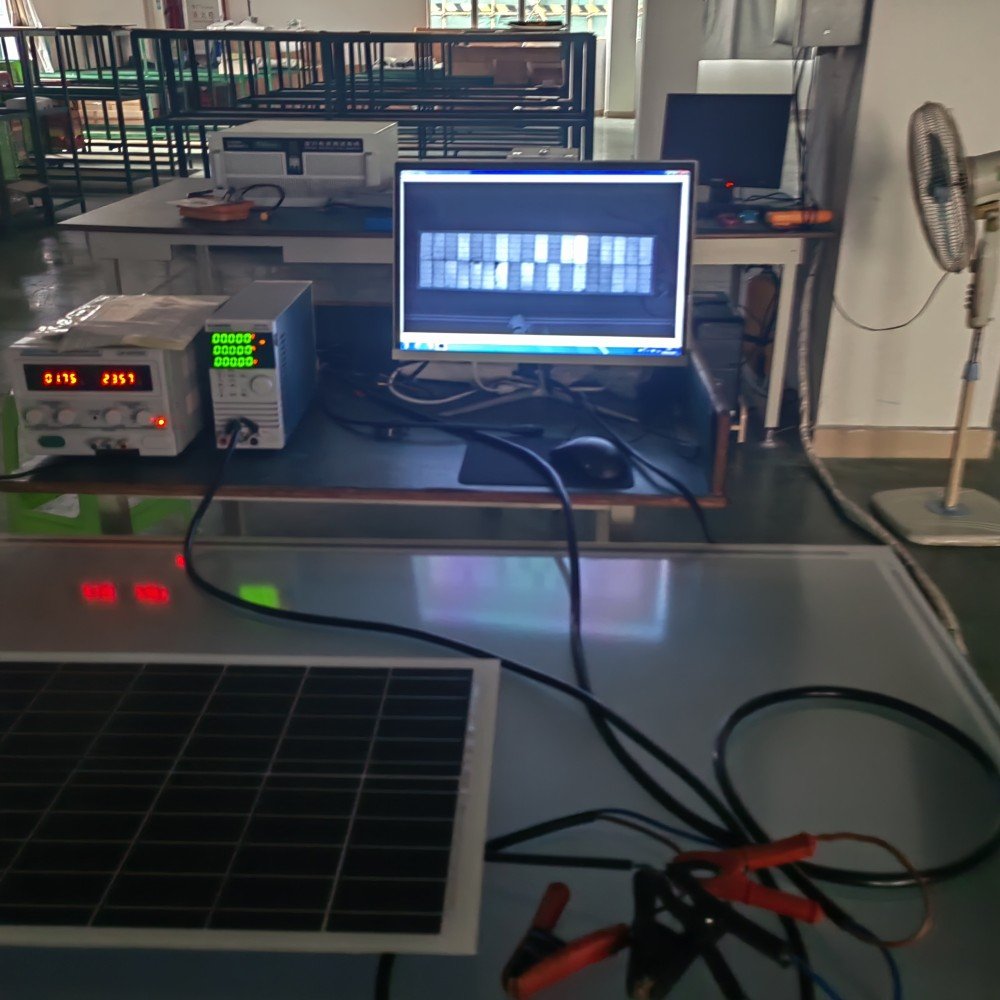

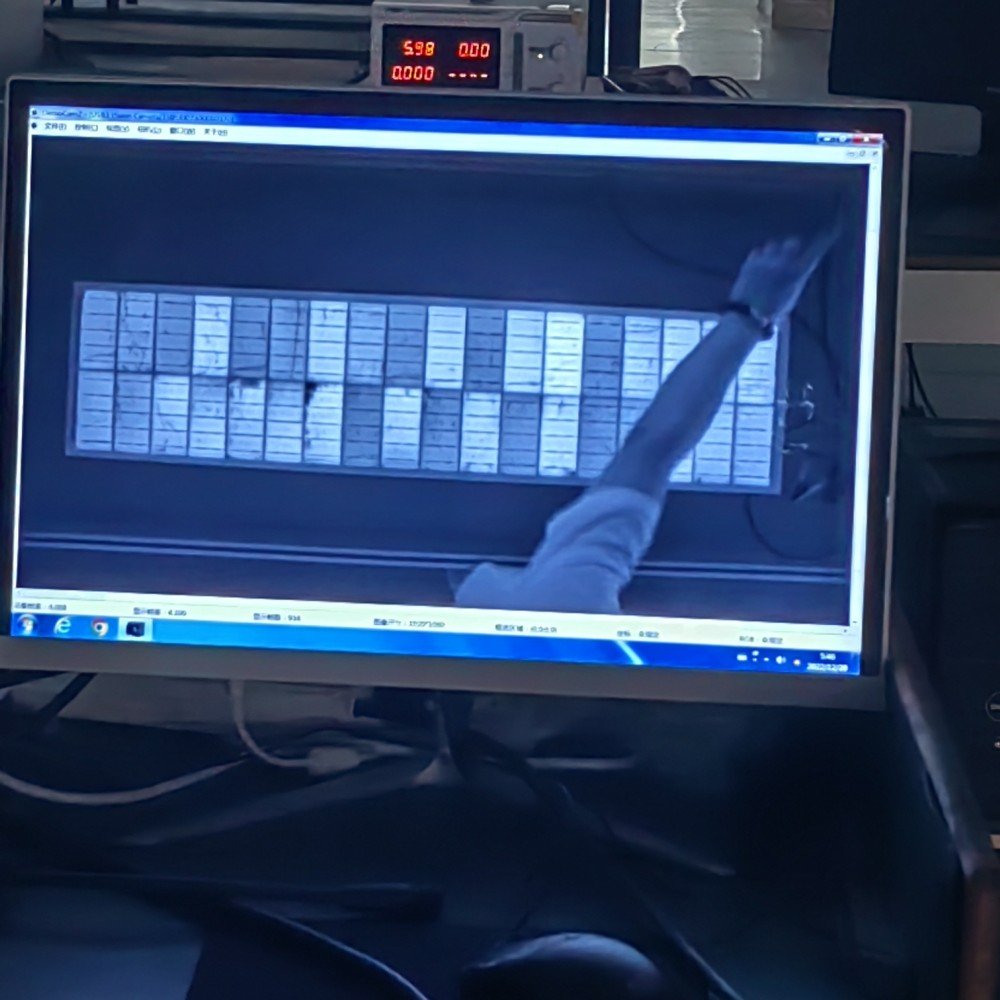

Here are some photos of our PRODUCT TESTING

1. SOLAR PANEL

–QUALIFIED solar panel.

Under the simulated sunlight, we can see that every part of the solar panel is evenly illuminated by the test instrument. This shows that it is made of A-grade solar cells.

–UNQUALIFIED solar panel.

Cracks and black spots are exposed, which will lead to a decrease in the power generation efficiency, uncertain service life, and potential safety hazards.

Some manufacturers use inferior raw materials to reduce costs, if there is no testing instruments, customers can not see the problem of the product.

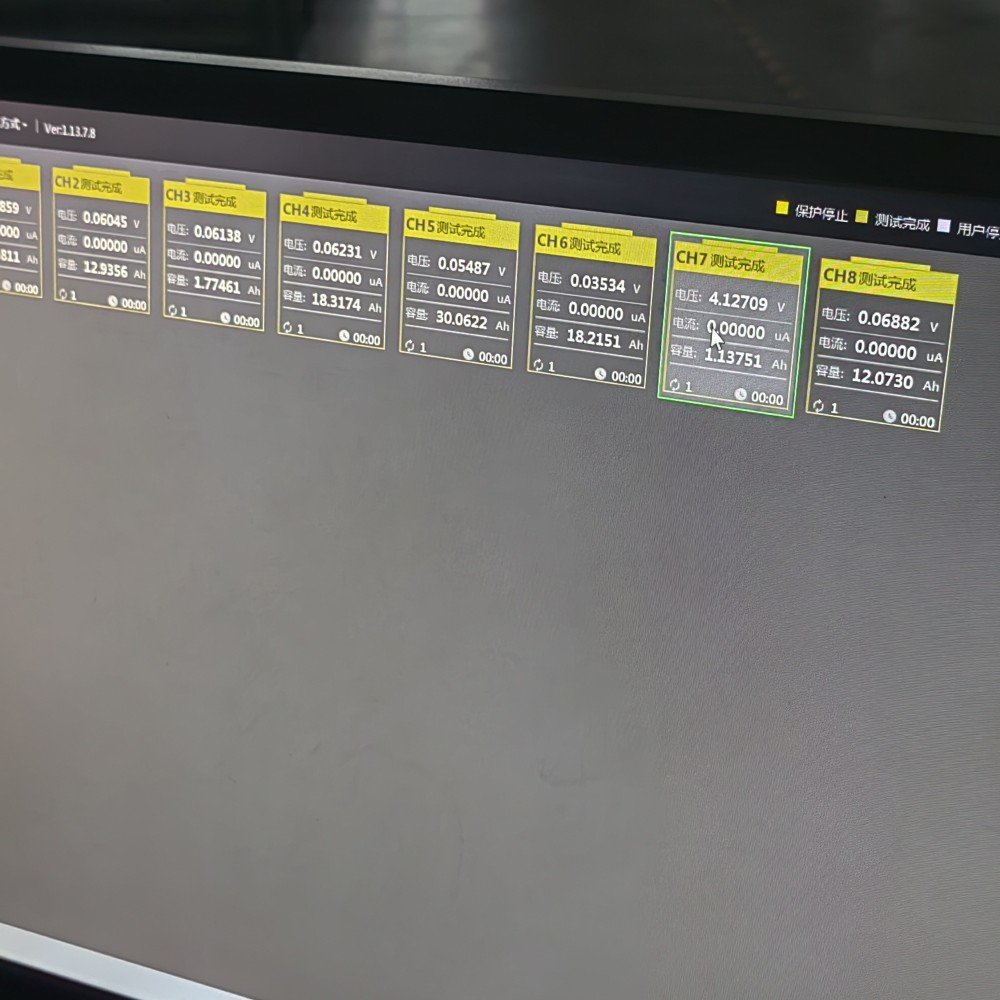

2. BATTERY

Test the actual battery capacity and the number of charge and discharge cycles.

Voltage, current, capacity and other parameters can be seen from the test instrument.

3. SOLAR LIGHT

The EL testing machine is also be used to test a solar light by simulating sunlight to check out the service life, work time, luminance and so on.

We are very confident that our product quality has advantages among peers, and our products are cost-effective to attract high-quality customers.