Last month, at an exhibition in Vietnam, a customer asked about the IP rating of our solar lights. I mentioned that most of our products are rated at IP65, with one being IP66. The customer seemed very surprised and questioned whether I was sure. He mentioned that the market now mostly has IP66 or even IP67 products, and he was quite astonished that our lights had such a low protection level.

上个月在越南参展展会的时候,有一个客户询问我们的太阳能灯IP等级是多少,我说大部分产品是IP65,一款是IP66,客户表现得很惊讶并反问我确定吗?他说现在市场上的都是IP66甚至IP67的,我们灯具的防护等级这么低让他很诧异。

I know that it’s not just the Vietnamese market, but throughout Southeast Asia, the Middle East, Africa, and mainstream household solar lights in Asia, the market is dominated by ABS plastic solar lights with fake parameters. For example, a light with an actual power of 3W is labeled as 50W; one with an actual power of 10W is labeled as 1000W. So, it’s quite normal for them to claim that their products have IP66 and IP67 ratings.

我知道不只是越南市场,整个东南亚、中东、非洲、亚洲主流的家用太阳能灯具都是以虚假参数的ABS塑料太阳能灯为主,譬如实际功率3W,标注功率50W;实际功率10W,标注功率1000W。所以他们对外声称自己是IP66和IP67是很正常的现象。

This made me think about what the minimum protection level for solar lights should be and why. What are the testing standards? What are the main considerations for waterproof design? To clear up this confusion, I consulted with the company’s structural engineer. He explained the answers to me by showing product structure diagrams and actual product comparisons. We also discussed other concerns of customers, such as how to replace components (light source modules, batteries, controllers, sensor probes), how to prevent corrosion of the lamp body, and shared case studies. I will describe all of these below.

这让我思考,太阳能灯防护等级最少要达到多少,为什么?测试的标准是怎样的?防水设计的主要考虑因素是什么?为了解开这个疑惑,我询问了公司的结构工程师,他通过展示产品结构图、实物对比为我解答,并我们对其他客户关心的问题展开了讨论,譬如如何更换配件(光源模组、电池、控制器、感应探头),灯体如何防腐蚀以及案例分享。下面我都将一一描述。

Protection Requirements for Solar Lights 太阳能灯防护等级要求

The minimum IP protection level for solar lights should be IP65. Here are the reasons:

太阳能灯具的防护IP等级最低应为IP65。以下是原因:

- Dust Protection (IP6X): The “6” in IP65 indicates complete protection against dust ingress. This is crucial for outdoor solar lights, as they are exposed to external environments for extended periods. Dust protection prevents dust, sand, and other particles from entering the lamp, affecting the circuitry or reducing light efficiency.

- 防尘能力(IP6X): IP65中的“6”表示完全防止灰尘进入。这对于户外使用的太阳能灯具非常重要,因为它们长期暴露在外部环境中,防尘能力能够防止灰尘、沙粒等进入灯具内部,影响电路或降低光效。

- Water Protection (IPX5): The “5” in IP65 means it can withstand low-pressure water jets from any direction without being affected. For solar lights, water resistance is critical as they may be used in various weather conditions, including heavy rain and humid environments. An IPX5 water protection level ensures that the lamp continues to work normally in these environments without malfunctioning or being damaged.

- 防水能力(IPX5): IP65中的“5”表示可以防止来自任何方向的低压水柱喷射而不受影响。对于太阳能灯具,防水能力至关重要,因为它们可能会在各种气候条件下使用,包括暴雨、潮湿的环境等。IPX5的防水等级能够确保灯具在这些环境中继续正常工作,而不发生故障或损坏。

IP65, as the minimum protection level, offers adequate dust and water protection, ensuring that solar lights can operate stably in harsh outdoor conditions for an extended period. This is crucial for extending the lifespan of the lamps and ensuring their performance. For more detailed descriptions of protection levels, you can read my other article: https://gcotsolar.com/what-does-the-ip-rating-of-outdoor-solar-lights-stand-for/

IP65作为最低防护等级,可以提供足够的防尘和防水保护,确保太阳能灯具在户外恶劣条件下能够长时间稳定运行。这对于延长灯具的使用寿命和保证其性能非常关键。更多关于防护等级的描述可阅读我的另一篇文章: https://gcotsolar.com/what-does-the-ip-rating-of-outdoor-solar-lights-stand-for/

Should the protection level reach IP66 or even IP67? This depends on the usage environment and application scenarios:

是否需要达到IP66甚至是IP67呢,这取决于灯具的使用环境和应用场景:

IP66 Rating means that the light can fully prevent dust ingress and will not be penetrated by water even when subjected to powerful water jets. If the light frequently faces heavy rainfall, strong sandstorms, or other harsh weather conditions, an IP66 water protection level is essential. It ensures that the light continues to function normally in high-pressure water environments, without water seeping in and damaging the internal electronic components.

IP66等级意味着灯具能够完全防止灰尘进入,并且在受到强力喷水时也不会被水侵入,如果灯具需要经常暴露在强降雨、大风沙等恶劣天气中,IP66防水等级是非常有必要的。它可以确保灯具在高压喷水环境下仍然保持正常工作,不会因水分渗入而损坏内部电子元件。

IP67 Rating not only provides the dust protection of IP66 but also allows the light to be temporarily submerged in water at a certain depth (usually 1 meter for 30 minutes) without being damaged. This means that even if the light accidentally falls into water or is installed near a water source where it might be submerged, the light’s safety and functionality are ensured.

IP67等级除了具备IP66的防尘性能外,还可以在一定深度的水中短时间浸泡(通常为1米深度的水中浸泡30分钟)而不受损。这意味着即使灯具意外掉入水中,或者安装在水边可能被水淹没的地方,也能够保证灯具的安全性和功能性。

IP67 is suitable for more demanding environments, such as installations near water bodies (e.g., poolside, near fountains) or in areas frequently affected by floods. If the solar light is installed in these locations, achieving an IP67 protection level offers higher safety assurance, preventing damage due to accidental submersion.

IP67等级适用于更为严苛的环境,如靠近水体的安装场景(如池畔、喷泉附近)或经常遭受洪水侵袭的地区。如果太阳能灯具安装在这些位置,达到IP67防水等级可以提供更高的安全保障,防止因意外浸水而导致设备损坏。

For most regular outdoor solar lights, an IP65 water protection level is usually sufficient to resist rain and dust erosion, ensuring stable long-term outdoor operation. If the environment faces extreme weather conditions or the light is installed near water bodies, upgrading to an IP66 or IP67 water protection level is necessary.

对于大多数常规户外使用的太阳能灯具,IP65的防水等级通常足够,能够抵御雨水和灰尘的侵蚀,确保灯具在户外长期稳定运行。如果使用环境遭遇极端天气条件,或者灯具安装在靠近水体的地方,那么升级到IP66或IP67防水等级则是必要的。

Waterproof Test Standards 防水测试标准

There are many waterproof test standards. We follow GBT 4208-2017/IEC 60529:2013. The following is a detailed description of the test content:

防水测试标准有多种,我们遵循的是GBT 4208-2017/IEC 60529:2013,以下是关于测试内容的具体说明:

| The second characteristic number 第二位特征数字 | Test Methods 试验方法 | Water Flow Rate 水流量 | Duration of The Trial 试验持续时间 | Test conditions refer to the chapter 试验条件参见章条 |

| 5 | Use the nozzle shown below, the nozzle diameter is 6.3mm, the distance is 2.5m~3m 使用下图喷嘴,喷嘴直径6.3mm,距离2.5m~3m | (12.5±0.625) L/min | 1 min/㎡ at least 至少 3min | 14.2.5 |

| 6 | Use the nozzle shown below, the nozzle diameter is 12.5mm, and the distance is 2.5m~3m 使用下图喷嘴,喷嘴直径12.5mm,距离2.5m~3m | (100±5) L/min | 1 min/㎡ at least 至少 3min | 14.2.6 |

| 7 | 使用潜水箱,水面在外壳顶部以上至少0.15m,外壳底面在水面下至少1m | – | 30 min | 14.2.7 |

For tests from IPX1 to IPX6, the temperature difference between the water temperature and the test specimen should not exceed 5K. If the water temperature is lower than the test specimen by more than 5K, the pressure inside and outside the enclosure should be kept balanced.

进行 IPX1至IPX6的试验,水温与试验时试样的温差应不大于5K。 如果水温低于试样超过 5K, 应使外壳内外保持压力平衡。

Examples of Waterproof Rating Requirements for Solar Lights with IPX5 and IPX6 Ratings:

以IPX5和IPX6这两种太阳能灯具所需要的防水等级要求为例:

IPX5 Rating – 6.3 mm Nozzle Test 第二位特征数字为5的6.3 mm喷嘴试验

For devices with a second characteristic digit of 5, the standard test involves using a 6.3 mm nozzle to spray water on the enclosure from all possible directions. The required test conditions are as follows:

对于第二位特征数字为5的设备,标准测试使用6.3 mm喷嘴从所有可能的方向向外壳喷水。要求的测试条件如下:

- Nozzle diameter 喷嘴内径: 6.3 mm;

- Water flow rate 水流量: (12.5 ± 0.625) L/min;

- Water pressure 水压: Adjusted according to the specified water flow rate 按规定水流量调节;

- The central part of the main water stream 主水流的中心部分: Forms a circle with a diameter of approximately 40 mm at a distance of 2.5 m from the nozzle 离喷嘴2.5 m处直径约为40 mm的圆;

- Water spraying time per square meter of enclosure surface 外壳表面每平方米喷水时间: About 1 min 约1分钟;

- Test duration 测试时间: At least 3 min 最少3分钟;

- Distance from nozzle to enclosure surface 喷嘴至外壳表面的距离: 2.5 m to 3 m.

IPX6 Rating – 12.5 mm Nozzle Test 第二位特征数字为6的12.5 mm喷嘴试验

For devices with a second characteristic digit of 6, the standard test involves using a 12.5 mm nozzle to spray water on the enclosure from all possible directions. The required test conditions are as follows:

对于第二位特征数字为6的设备,标准测试使用12.5 mm喷嘴从所有可能的方向向外壳喷水。要求的测试条件如下:

- Nozzle diameter 喷嘴内径: 12.5 mm;

- Water flow rate 水流量: (100 ± 5) L/min;

- Water pressure 水压: Adjusted according to the specified water flow rate 按规定水流量调节;

- The central part of the main water stream 主水流的中心部分: Forms a circle with a diameter of approximately 40 mm at a distance of 2.5 m from the nozzle 离喷嘴2.5 m处直径约为120 mm的圆;

- Water spraying time per square meter of enclosure surface 外壳表面每平方米喷水时间: About 1 min 约1分钟;

- Test duration 测试时间: At least 3 min 最少3分钟;

- Distance from nozzle to enclosure surface 喷嘴至外壳表面的距离: 2.5 m to 3 m.

Product Structural Waterproof Design 产品结构防水设计

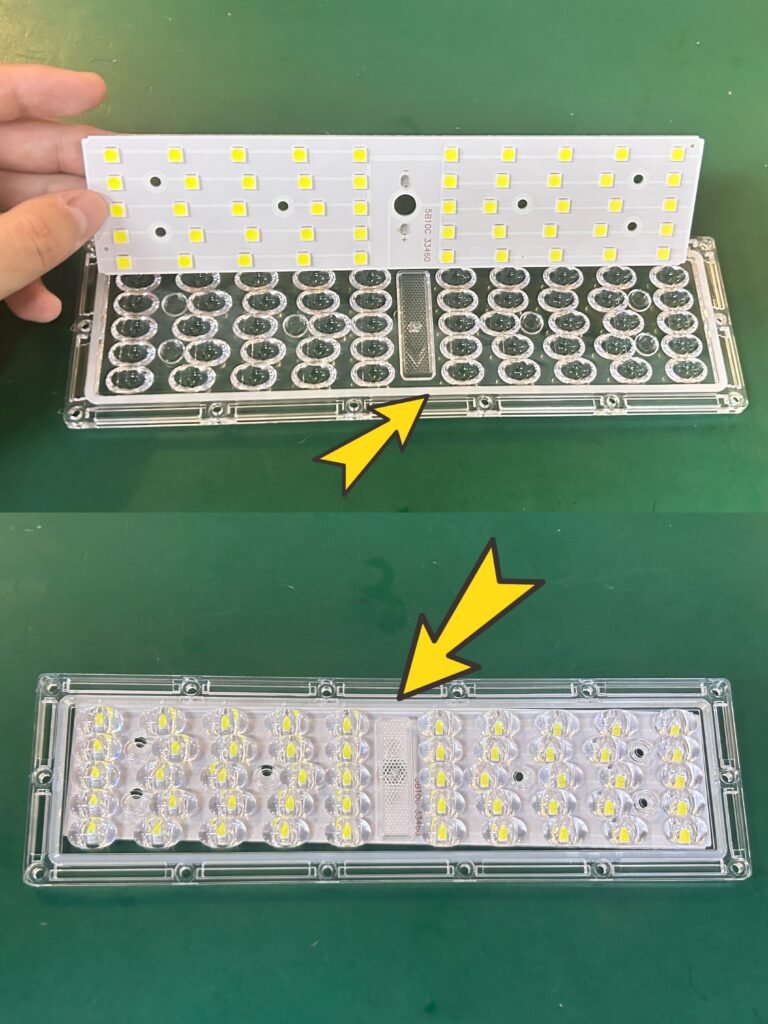

To achieve effective waterproofing, the structural design of the product is crucial. The white waterproof gasket in the image is positioned between the LED light source lens and the aluminum baseboard. Its primary function is to fill gaps and prevent external water ingress, thereby ensuring the waterproof capability of the solar light.

为了实现有效防水,产品的结构设计至关重要。图中白色防水垫片位于LED光源透镜与铝基板之间,其主要作用是填补缝隙,防止外部水渗入,从而保证太阳能灯的防水能力。

Battery Waterproofing 电池防水

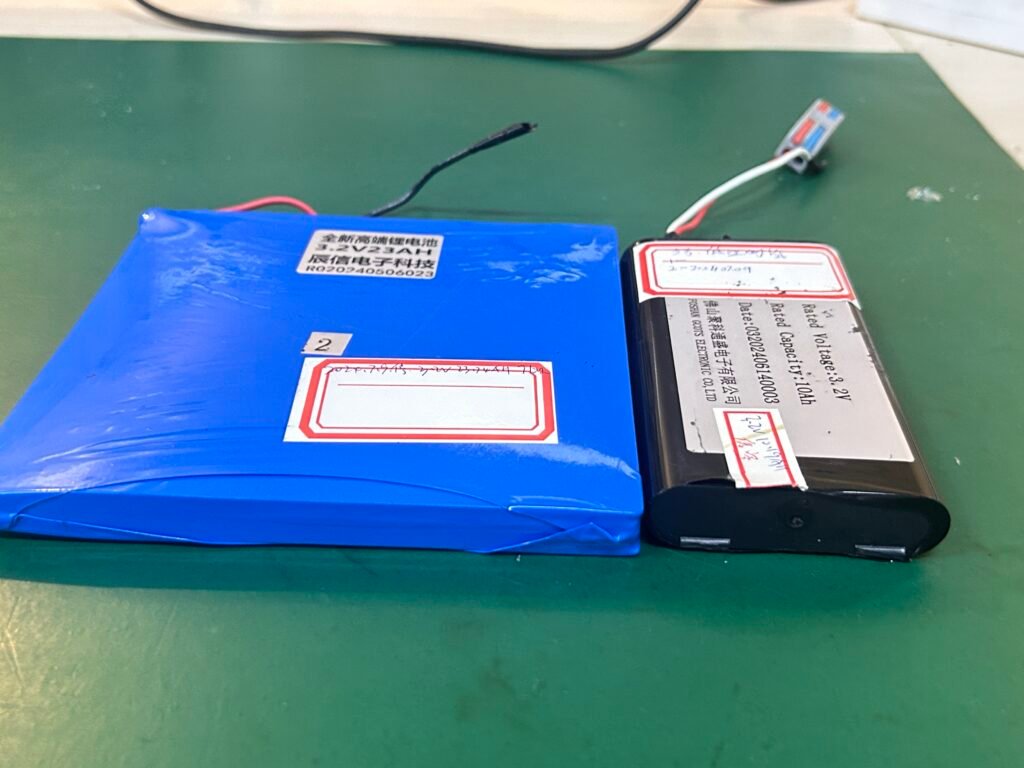

Currently, most solar lights do not specifically waterproof the internal battery; they rely solely on the insulation glue to provide separation. However, if a significant amount of water immerses the battery, there is a high risk of battery damage. A high-quality waterproofing method involves encapsulating the battery with resin.

电池的防水方面,目前大部分太阳能灯没有特意对内部的电池做防水,仅仅是依靠本身的绝缘胶来实现隔绝,但是如果进水量足够多把电池浸泡住了会有较高风险损坏电池。有一种较为优质的防水方式是对电池实施灌胶封装。

First, prepare the battery pack, which includes multiple cells, necessary circuits, and protection boards. Place the battery pack into a specially designed resin mold to ensure it is securely fixed in place.

将包括多个电芯的组装以及必要的电路和保护板的电池包准备好,将电池包放入专门设计的灌胶模具中,确保电池包能够稳固地固定在模具中。

Next, pour the resin material into the mold, which will fill all the internal voids of the battery pack. The resin material should be epoxy resin, silicone, or polyurethane, as these offer excellent insulation properties and chemical resistance. During the resin pouring process, control the flow rate to avoid bubbles or uneven distribution. Sometimes, vacuum encapsulation technology is used to remove air bubbles and ensure the resin completely covers all parts of the battery pack.

然后将灌胶材料倒入模具中,灌胶材料会填充电池包内部的所有空隙,灌胶材料应选择环氧树脂、硅胶或聚氨酯等,它们具有优良的绝缘性能和耐化学性。灌胶过程中需要控制材料的流速,以避免产生气泡或不均匀分布。有时会采用真空灌胶技术,以去除空气中的气泡,确保灌胶材料能够完全覆盖电池包的各个部分。

After encapsulation, allow the material to cure at room temperature or in a heated environment. The curing time depends on the type of material used and the ambient temperature. During the curing process, the resin gradually hardens, forming a solid protective layer that completely seals the battery pack. The encapsulation process not only provides effective waterproofing but also offers thermal insulation, which can help extend the battery’s lifespan in high-temperature regions, as shown in the battery pack on the right side of the image.

灌胶完成后,需要让材料在室温或加温环境下固化。固化时间取决于所用材料的种类和环境温度。在固化过程中,灌胶材料会逐渐变硬,形成一个坚固的保护层,将电池包完全密封。灌胶工艺不仅能有效防水,还可以起到隔热作用,对于高温地区使用太阳能灯该方法也有利于延长电池使用寿命。如上图右方的电池包所示。

Although encapsulation can effectively waterproof products, it is not widely used due to its high cost. Additionally, if the external waterproofing of the solar light is well done, there will be little to no water entering the light housing. Even if a small amount of rainwater does enter, adding drainage holes can improve protection since solar lighting operates at low voltage. As long as the electronic components are properly drained, the quality of the light fixture will not be affected.

灌胶工艺虽然可以有效防水,但是使用该工艺的产品并不多,首先因为成本较高,其次因为太阳能灯具外部做好了防水措施就不会有水留到灯壳里,即使有少量雨水进入内部,如果增加漏水孔也能提高防护能力,因为太阳能是低压方案,只要电子元件的部位做好排水,是不影响灯具质量的。

Controller Waterproofing 控制器防水

Currently, the mainstream protective method for controllers is also encapsulation. However, regardless of the internal components’ protection, the waterproof structure of the light housing should be carefully considered to prevent rainwater from entering the light fixture. On one hand, it is challenging to achieve perfect waterproofing at the wiring positions, and on the other hand, it helps save costs.

控制器目前主流的防护手段也是使用灌胶工艺,但无论内部的部件使用再好的防护工艺,我们还是要把灯壳的防水结构考虑好,尽量防止雨水进入到灯具内部,一方面是接线位置无法做到尽善尽美的防水,另一方面也是节省成本。

A friend of mine, who is a product manager at a lighting company in Shenzhen, inquired about how to waterproof split-type solar street lights. The reason is that he tested many samples from solar kit suppliers in Zhongshan, and their waterproofing mostly failed, sharing their test reports.

我一个朋友,他是深圳一家照明企业的产品经理,跟我询问分体式太阳能路灯如何防水。原因是他测了很多中山的太阳能套件供应商样品,防水基本过不了,并分享了他们的测试报告。

They used a nozzle with 100 holes, 120 mm in diameter, with a water flow rate of 10 liters per minute, spraying continuously for 5 minutes at a distance of 0.3-0.5 meters from the sample. They found that water entered the light fixture through gaps on both sides, failing to meet the IP65 waterproof standard.

他们使用100孔、直径120MM的喷嘴以每分钟10L的水流量在距离样品0.3-0.5米的距离,270°范围持续喷水5分钟,最终发现两边缝隙会有水进入到灯具内部,并没有达到他们IP65的防水要求。

I believe these Zhongshan factories are aware of this issue. Their product shipping standards are based on actual usage scenarios, as rainwater does not fall from below. Therefore, the waterproofing requirements for the bottom of the fixture are not strictly designed to IP65 standards. They consider this approach more cost-effective, which is reasonable. From my friend’s perspective, since the product is promised to have an IP65 protection level, it should meet this standard in all areas of the fixture. Different companies have different product philosophies—what is your preference for partnering with a company?

我认为这些中山的工厂是知道会有这个情况出现,他们产品出货标准是根据实际应用情景去考虑,因为雨水不会从下往上降落,所以对于灯具下方的防水要求并不会严格依照IP65标准去设计。他们认为这样更有性价比,这样做有合理性。从我朋友的角度看既然承诺给客户产品是IP65防护等级就应该整灯所有地方都能达到这个标准,也没有问题,不同公司有不同的产品理念,不知道阅读文章的你更与偏向哪一类公司合作?

In the image, the main factor causing water ingress is the too-large spacing of the screws on the lens, leading to insufficient downward pressure. When there is a certain water pressure, if the waterproof sealant deforms, gaps will form, allowing water to seep in. If molds are already made, using thicker and harder waterproof gaskets is the only solution. However, if the gasket is too thick and hard, it may not compress properly, so a balance must be struck.

图片中这个产品进水的主要因素是透镜上的螺丝的间距太大,导致下压力不够大,当有一定水压冲刷缝隙时如果防水胶变形就会产生缝隙从而有水渗进去。假设已经开好模具的情况下,只能使用厚一些和硬一些的防水胶圈,但是这个胶圈太厚太硬压不下去也不行,所以得有一个平衡。

Convenient Replacement of Solar Light Components 便捷更换太阳能灯具配件

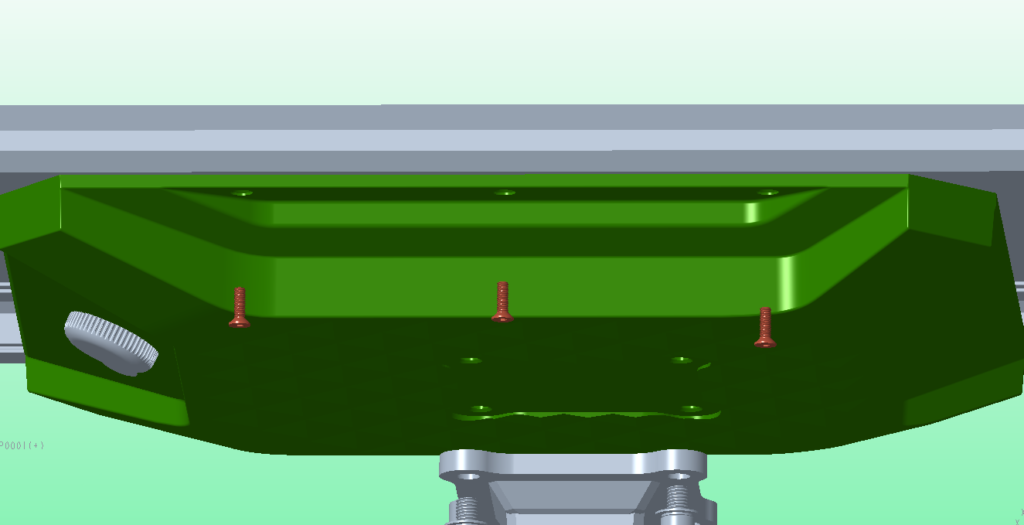

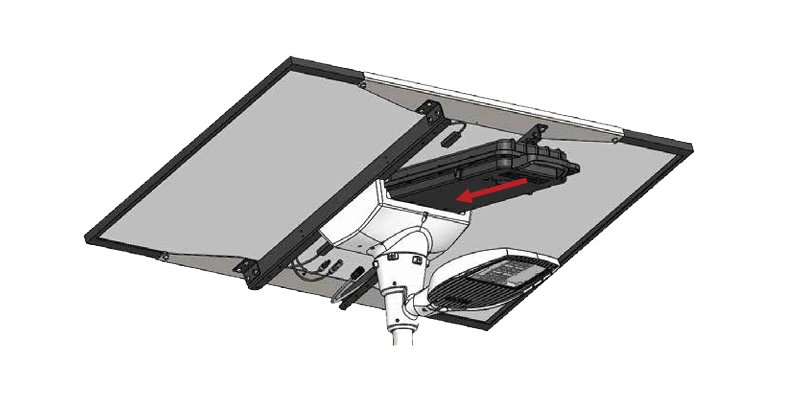

Regarding the convenient replacement of solar light source modules, internal batteries, controllers, sensors, and other components, customer interest is increasing. I will analyze this from old to new designs, using our popular all-in-one solar street light SL-AIO-XC as an example. The image below shows that this product requires unscrewing to open the battery compartment and remove the components inside. The drawback is that once the light is installed on a pole, the entire light fixture must be dismantled to perform this operation. The screws connect the battery compartment to the photovoltaic panel assembly, so unscrewing means separating the photovoltaic panel from the battery compartment. Achieving this at a height is quite challenging, so while this method allows component replacement, it is not very convenient.

关于如何便捷更换太阳能灯具光源模组,以及内部电池、控制器、感应探头等配件的问题,越来越受到客户的关注。我将会从旧设计到新设计去分析,首先以我们最受欢迎的一体式太阳能路灯SL-AIO-XC为例,下方图片显示这款产品打开电池仓的方式是扭下螺丝然后可以取下里面的配件,缺点是当灯具被安装上灯柱之后,需要把整个灯具拆下来才能完成这个操作,因为螺丝是把电池仓和上面光伏板的套件相连的,扭下螺丝意味着光伏板会和电池仓分离,要在高空实现一些列的操作难度很大,所以这样的方式尽管可以实现配件更换,但是不够便捷。

To complete the replacement more quickly, we plan to add a “door” directly on the battery compartment. We applied this design to another solar floodlight product, where a screw switch at the back of the battery compartment allows for battery replacement by simply unscrewing it. This can be accomplished in just a few minutes, even if the light fixture is mounted on a wall.

为了在更短的时间内完成更换,我们希望在电池仓上直接开一个“门”,在另一款太阳能投光灯产品上我们应用了这个设计,在后方电池仓位置有螺丝开关的设计,只要扭下螺丝就可以更换电池,即使灯具挂在墙上也只需要几分钟就能完成更换。

In addition to the above two structures, we are developing a new product structure that makes replacement even easier. The entire battery compartment can be removed by simply gripping the handle and pulling it out.

除了以上两种结构,我们还有一款开发中的产品结构能更方便,只需要握住电池仓的把手轻轻往外一拉就能取出整个电池仓。

Surface Treatment Processes 表面处理工艺

The most crucial factor in preventing corrosion of light fixtures is the surface treatment process. Currently, mainstream solar lights use ABS plastic, sheet metal, and aluminum (die-cast aluminum and aluminum profiles). Suitable surface treatment processes for these materials include high-temperature electrostatic spraying, electrophoretic coating, hot-dip galvanizing, anodizing, and anti-corrosion primer spraying. However, in practice, only high-temperature electrostatic spraying and anti-corrosion primer spraying are commonly used. Why is this the case?

灯具外壳防腐蚀最关键的影响因素是表面处理工艺,现在主流的太阳能灯具使用ABS塑料、钣金、铝(压铸铝和铝型材),适合它们的表面处理工艺包括高温静电喷涂、电泳涂层、热浸镀锌、氧化处理、喷涂防腐底漆工艺,然而实际应用中的只用到高温静电喷涂和喷涂防腐底漆这两种工艺,这是为什么呢?

Firstly, electrophoretic coating is typically applied to metal materials and is relatively expensive. Anodizing is usually used for aluminum, but die-cast aluminum surfaces have many pores and uneven surfaces, making anodizing difficult. Moreover, anodizing has weaker corrosion resistance and impact resistance compared to sprayed coatings in outdoor environments. Hot-dip galvanizing is typically used on lamp posts rather than the lights themselves because it is easier to ensure even coverage with zinc on simpler shapes. Complex shapes, narrow gaps, or internal structures of lights risk uneven coverage.

首先电泳涂层工艺通常应用在金属材料上,且成本较高;阳极氧化通常用于铝材,但压铸铝表面会多气孔,不均匀的表面难以进行氧化处理,且该工艺在户外环境中没有喷涂涂层厚,耐腐蚀抗击打能力较弱;热浸镀锌通常用于灯杆上而不是灯具上,因为热镀锌液体在覆盖物体时,较简单形状的物体更容易确保锌液均匀覆盖,而复杂形状、狭窄缝隙或内部结构的灯具可能会有覆盖不均的风险。

Therefore, ABS plastic usually uses anti-corrosion primer spraying, while sheet metal and aluminum use high-temperature electrostatic spraying. Plastics are prone to deformation at high temperatures, making high-temperature electrostatic spraying unsuitable for them. The following is a comparison of the two processes:

因此ABS塑料通常使用喷涂防腐底漆工艺,钣金和铝材使用高温静电喷涂工艺,塑料在高温下容易发生形变所以无法适用高温静电喷涂工艺。以下是两种工艺的对比信息:

| Process Stage 工序阶段 | Anti-Corrosion Primer Spraying 防腐底漆喷涂工艺 | High-Temperature Electrostatic Spraying 高温静电喷涂工艺 |

| 1. Surface Treatment 表面处理 | Cleaning and degreasing to ensure the surface is free of stains, grease, and dust. 清洁和除油,确保表面无污渍、油脂和灰尘。 | Cleaning and degreasing, sandblasting, or sanding the surface to increase adhesion. 清洁和除油,喷砂或打磨处理表面,增加附着力。 |

| 2. Primer Spraying 底漆喷涂 | Spray anti-corrosion primer evenly covering the surface. 喷涂防腐底漆,涂层均匀覆盖表面。 | Not applicable, proceed directly to the next step. 不适用,直接进行下一步。 |

| 3. Drying or Curing 烘干或固化 | Usually air-dried or cured at low temperatures. 通常在常温或低温下烘干或固化防腐底漆。 | Preheat the product to the appropriate spraying temperature. 预热产品至适合喷涂温度。 |

| 4. Powder Spraying 粉末喷涂 | Not applicable, the process ends here. 不适用,工序结束。 | Uniformly spray powder coating onto the workpiece using an electrostatic powder gun. 通过静电粉末喷枪将粉末涂料均匀喷涂在工件上。 |

| 5. High-Temperature Curing 高温固化 | Not applicable, the process ends here. 不适用,工序结束。 | Place the coated workpiece in a high-temperature curing oven, usually at 180°C-200°C for 20-30 minutes. 将喷涂好的工件放入高温固化炉中,通常在180°C-200°C固化20-30分钟。 |

| 6. Quality Inspection 质量检查 | Inspect the adhesion, uniformity, etc., of the anti-corrosion primer. 检查防腐底漆的附着力、均匀性等。 | Inspect the cured coating quality, including adhesion, hardness, color consistency, etc. 检查固化后的涂层质量,包括附着力、硬度、颜色一致性等。 |

Comparison Summary 对比总结

Number of Steps: The high-temperature electrostatic spraying process involves more steps, including preheating, powder spraying, and high-temperature curing. In contrast, the anti-corrosion primer spraying process is simpler, typically completed after spraying and curing.

工艺步骤数量:高温静电喷涂工艺的步骤较多,涉及到预热、粉末喷涂和高温固化等,而防腐底漆喷涂工艺则相对简单,通常在喷涂和固化后即完成工序。

Temperature Requirements: High-temperature electrostatic spraying requires higher temperatures to cure the coating and is suitable for metals and other heat-resistant materials. Anti-corrosion primer spraying is usually suitable for plastics and some low-heat-resistant materials.

温度要求:高温静电喷涂需要更高的温度来固化涂层,适用于金属等耐高温材料;而防腐底漆喷涂通常适用于塑料和一些低耐热材料。

Applications: High-temperature electrostatic spraying is primarily used for metal surfaces that need wear and corrosion resistance, while anti-corrosion primer spraying is used for materials requiring basic anti-corrosion protection.

用途:高温静电喷涂主要用于需要耐磨、耐腐蚀的金属表面处理,而防腐底漆喷涂适用于需要基础防腐保护的材料。

High-temperature electrostatic spraying can form a thicker, more uniform coating. After high-temperature curing, the powder coating has a stronger bond with the workpiece surface, making it less likely to peel off. The electrostatic powder coating also has high abrasion resistance and UV resistance, maintaining its protective function for extended periods in outdoor environments without aging or damage. Therefore, the corrosion protection effect of high-temperature electrostatic spraying is usually superior.

高温静电喷涂工艺能够形成更厚、更均匀的涂层,经过高温固化后,粉末涂层与工件表面之间的结合力更强,不易脱落。且静电喷涂的粉末涂层具有较高的耐磨性和抗紫外线能力,在户外环境中能够长时间保持其防护功能,不易老化或破损。因此高温静电喷涂工艺的防腐效果通常会更好。

By integrating both advanced surface treatment processes and comprehensive waterproofing measures, manufacturers can significantly enhance the reliability and lifespan of their solar lighting products. This approach not only ensures that the fixtures perform optimally in diverse conditions but also provides long-term value and satisfaction to customers.

通过整合先进的表面处理工艺和全面的防水措施,制造商可以显著提高其太阳能照明产品的可靠性和使用寿命。这种方法不仅能确保装置在不同条件下发挥最佳性能,还能为客户提供长期价值和满意度。